Physical structure of ion exchange resin

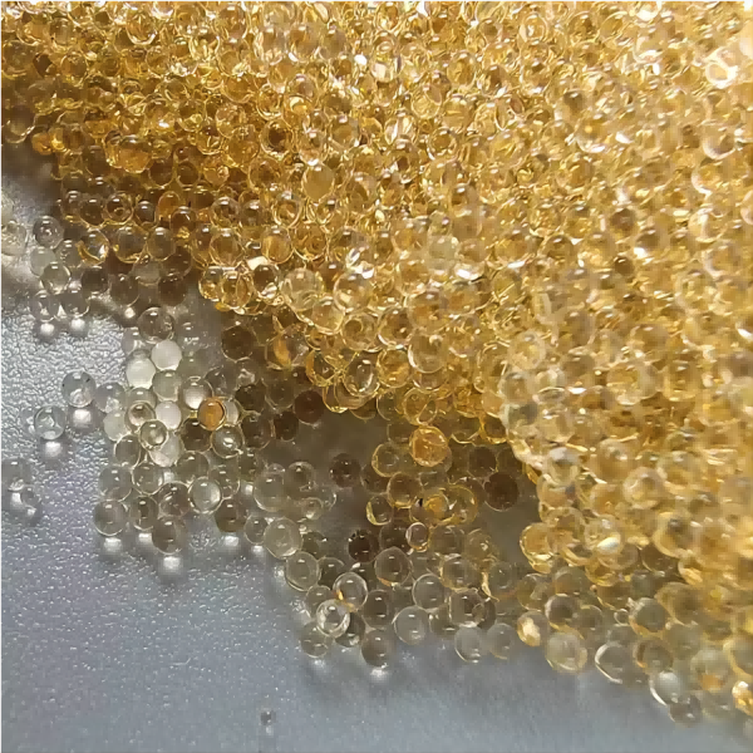

Ionic resins are often divided into two categories: gel type and large pore type.

A polymer skeleton of a gel type resin with no internal pores in the dry condition. It expands when it absorbs water, forming very fine pores between the macromolecular chain nodes, often called micro-pore. The average pore size of the wet resin is 2 ~ 4nm(2×10-6 ~ 4×10-6mm).

This kind of resin is more suitable for adsorption of inorganic ions, their diameter is small, generally 0.3 ~ 0.6nm. This kind of resin can not adsorb large molecular organic substances, because the latter size is large, such as protein molecules with a diameter of 5 ~ 20nm, can not enter the microscopic pores of this kind of resin.

Macroporous resin is made by adding pore-causing agent during polymerization to form a porous cavernous structure skeleton with a large number of permanent micropores inside and then introducing exchange groups. It has both micro-pores and macro-pore, and the pore size of the wetting resin can be 100 ~ 500nm, and its size and quantity can be controlled at the time of manufacturing. The surface area of the pore can be increased to more than 1000m2/g. This not only provides good contact conditions for ion exchange, shorters the distance of ion diffusion, but also increases many chain active centers, and produces molecular adsorption through the intermolecular van de Waal's force, which can adsorb various non-ionic substances like activated carbon and expand its function. Some macroporous resins without exchange functional groups can also adsorb and separate a variety of substances, such as phenols in chemical plant wastewater.

The pores inside the macroporous resin are many and large, the surface area is large, the active center is many, the ion diffusion rate is fast, the ion exchange rate is also much faster, about ten times faster than the gel type resin. When used, the function is fast, high efficiency, and the required processing time is shortened. Macroporous resin also has a variety of advantages: swelling resistance, not easy to break, oxidation resistance, wear resistance, heat resistance and temperature change resistance, and easy adsorption and exchange of organic macromolecular substances, so strong pollution resistance, and easier to regenerate.