What is lon Exchange Resin?

Ion exchange resin is a type of polymer material with the ability to exchange ions in aqueous solutions. This resin is widely utilized in various industries, including water treatment, pharmaceuticals, and chemical processes. Its functionality lies in the exchange of positively or negatively charged ions with ions of similar charge in the surrounding solution. This process helps in selectively removing or concentrating specific ions, making ion exchange resin a valuable tool in purification, demineralization, and separation processes. The resin's versatility and effectiveness in controlling the composition of solutions make it a fundamental component in numerous industrial applications.

Advantages of lon Exchange Resin

Selective ion removal

Ion exchange resins can selectively remove specific ions from a solution, allowing for precise control over the composition of the treated material. This is particularly useful in water softening and purification processes.

Water treatment

One of the primary applications is in water treatment, where ion exchange resins can effectively remove hardness ions (such as calcium and magnesium) and other impurities, improving water quality for domestic and industrial use.

Chemical processing

In chemical industries, ion exchange resins are employed for purifying and separating various chemicals. They assist in the production of high-purity substances by selectively adsorbing or releasing specific ions.

Metal recovery

Ion exchange resins are utilized in metal recovery processes, helping to separate and concentrate valuable metals from complex solutions. This is crucial in recycling and resource recovery.

Why Choose Us?

R&D

Invests heavily in R&D, continuously improving their product offerings and staying at the forefront of new material technology. dedication to innovation means customers can benefit from cutting-edge solutions.

Customization services

Provide customization services to meet specific customer requirements, ensuring that clients receive products that exactly fit their needs.

Experienced team

The company employs a team of experienced professionals with expertise in new material technologies, ensuring that their products and services are backed by deep knowledge and technical proficiency.

24h online service

We try and respond to all concerns within 24 hours and our teams are always at your disposal in case of any emergencies.

The Manufacturing Process of lon Exchange Resin

Polymerization

The process typically begins with the polymerization of styrene and divinylbenzene (dvb). These monomers are combined in specific proportions to create a cross-linked polymer structure. The cross-linking provides stability and insolubility to the resin.

Bead formation

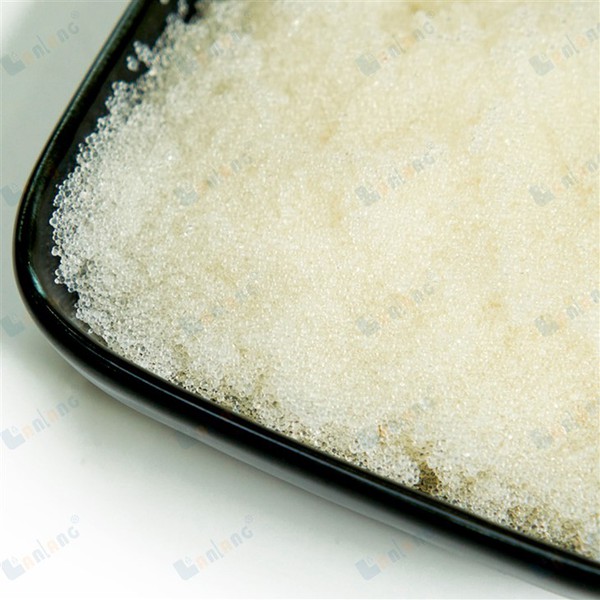

The polymerized mixture is then formed into small beads. The size of the beads can impact the properties of the resin, and different applications may require different bead sizes.

Functionalization - cation or anion exchange groups

The beads are functionalized by introducing specific functional groups onto the polymer matrix. For cation exchange resins, sulfonic acid groups or carboxylic acid groups may be introduced. For anion exchange resins, quaternary ammonium groups or amine groups may be added. This functionalization determines the type of ions the resin will exchange.

Washing and conditioning

The functionalized beads undergo washing processes to remove impurities and unreacted monomers. Conditioning steps may also be performed to prepare the resin for the ion exchange process.

Ionic exchange

The resin beads are exposed to a solution containing ions that will replace or exchange with the ions on the resin. This process imparts the ion exchange capability to the resin.

Neutralization

After ion exchange, the resin is neutralized to remove excess chemicals and adjust the ph. This step ensures that the resin is ready for its intended application.

Drying

The resin is dried to remove residual moisture. Proper drying is crucial to prevent bacterial growth and maintain the stability of the resin.

How to Choose lon Exchange Resin

Type of ions to be exchanged

Identify the ions present in the solution that need to be exchanged. Choose a resin with the appropriate functional groups for the targeted ions (cation or anion).

Water composition

Consider the overall composition of the water or solution, including the concentrations of different ions. This information helps determine the resin's capacity and selectivity.

Resin cross-linkage

The degree of cross-linkage in the resin affects its mechanical strength and swelling properties. High cross-linkage enhances stability but may reduce ion exchange capacity.

Application

Different resins are designed for specific applications, such as water softening, metal recovery, or chemical purification. Choose a resin that is tailored to your intended use.

Operating conditions

Evaluate the temperature, ph, and other operating conditions of your process. Some resins may perform better under certain temperature or ph ranges.

Regenerability

Determine if regenerability is crucial for your application. Some resins can be regenerated and reused, offering cost savings over time.

Particle size

Consider the particle size of the resin beads. Smaller beads may offer better kinetic performance but may be more challenging to handle in some systems.

Capacity and efficiency

Assess the resin's ion exchange capacity and efficiency in removing target ions. High capacity and efficiency are generally desirable but should be balanced with other factors.

Application of lon Exchange Resin

Water softening

Ion exchange resins are extensively used to remove hardness ions, such as calcium (ca2+) and magnesium (mg2+), from water. This process helps prevent scale formation in pipes and appliances.

Water purification

In water treatment plants, ion exchange resins are employed to remove contaminants, heavy metals, and undesirable ions, enhancing the overall quality of drinking water.

Chemical processing

Ion exchange resins play a crucial role in chemical industries for purifying and separating various chemicals. They facilitate the production of high-purity substances by selectively adsorbing or releasing specific ions.

Demineralization

Resins are used in demineralization processes to remove both cations and anions, producing ultra-pure water for applications in industries such as power generation and electronics manufacturing.

Metal recovery

In mining and metallurgy, ion exchange resins assist in recovering valuable metals from solutions, helping to reduce environmental impact and increase resource efficiency.

Wastewater treatment

Ion exchange resins are employed in treating industrial wastewater to remove pollutants, heavy metals, and unwanted ions before discharge.

Food and beverage industry

Resins are used for decolorization, deionization, and purification of food and beverage products. They help ensure the quality and compliance of the final products.

Nuclear power

Ion exchange resins are utilized in nuclear power plants for water purification and the removal of radioactive ions from coolant systems.

Catalysis

Some ion exchange resins with specific functional groups can act as catalysts in chemical reactions, facilitating reaction processes in various industries.

Biotechnology and pharmaceuticals

Resins are employed in the purification of pharmaceutical products and in biotechnological processes, helping to achieve high levels of purity in bio-products.

Electroplating

Ion exchange resins assist in maintaining the quality of electroplating baths by removing impurities and ensuring a stable environment for the plating process.

Hydrometallurgy

In the extraction of metals from ores, ion exchange resins aid in separating and recovering metals from leach solutions.

Things to Note When Using lon Exchange Resin

Compatibility

Ensure compatibility between the ion exchange resin and the materials used in the system, including housing, gaskets, and seals. Incompatibility can lead to corrosion or degradation.

pH Conditions

Be mindful of the pH conditions in your application. Different ion exchange resins have optimal pH ranges for performance. Operating outside these ranges may reduce efficiency and lifespan.

Temperature

Consider the temperature of the process. Some resins are more sensitive to temperature changes, and extremes can affect their performance.

Regeneration

If the ion exchange resin is regenerable, follow proper regeneration procedures as recommended by the manufacturer. Over-regeneration or improper regeneration can affect the resin's longevity and performance.

Flow Rates

Adhere to recommended flow rates to ensure proper contact time between the resin and the solution. High flow rates may lead to insufficient ion exchange, while low flow rates can result in inefficient use of the resin.

Pre-Conditioning

Some ion exchange resins may require pre-conditioning before use. Follow the manufacturer's guidelines on pre-soaking or pre-conditioning steps to optimize resin performance.

Loading Capacity

Be aware of the loading capacity of the resin, especially if dealing with high concentrations of ions. Operating the resin beyond its capacity may result in breakthrough and reduced effectiveness.

Backwashing

For systems with high fouling potential, consider incorporating backwashing procedures to remove accumulated debris and prevent clogging of the resin bed.

Monitoring and Testing

Regularly monitor the resin's performance through water analysis and conductivity measurements. Periodic testing helps identify when regeneration or replacement is necessary.

Particle Size Distribution

If using resins with a specific particle size, ensure that the distribution meets the requirements of your system. Uniform particle size distribution enhances flow characteristics and separation efficiency.

Storage Conditions

Store ion exchange resin in a dry environment to prevent moisture absorption. Improper storage can lead to degradation and a decrease in performance.

Counterions

Counterions are the ions associated with the functional groups in the resin when it is in its native or regenerated form. These counterions can be exchanged with other ions during the ion exchange process.

Cross-linking agents

Cross-linking agents, such as divinylbenzene (dvb), are used during the polymerization process to create a three-dimensional, cross-linked structure. The degree of cross-linking affects the resin's mechanical strength and swelling properties.

Polymer matrix

The backbone of the resin is a polymer matrix, typically made from cross-linked polystyrene or a similar polymer. The cross-linking provides stability and insolubility to the resin.

Functional groups

Functional groups are attached to the polymer matrix, and these determine the type of ions that the resin can exchange. The choice of functional groups (cationic or anionic) depends on the specific application.

Water

The resin typically contains a certain amount of water, and its moisture content can impact its performance. Proper drying is often part of the resin manufacturing process.

How to Maintain lon Exchange Resin

Regular monitoring

Periodically monitor the resin's performance through water analysis, conductivity measurements, or other relevant tests. Regular monitoring allows you to identify any changes in resin behavior and take corrective actions promptly.

Backwashing

Implement regular backwashing procedures to remove accumulated debris and prevent resin bed fouling. Backwashing helps maintain proper flow rates and prevents clogging.

Regeneration

If the ion exchange resin is regenerable, follow the manufacturer's guidelines for regeneration. This process involves replacing the adsorbed ions on the resin with fresh ions, restoring its ion exchange capacity. Over time, resin exhaustion may necessitate regeneration.

Optimal operating conditions

Ensure that the resin operates within the recommended temperature and ph ranges. Operating outside these conditions can affect the resin's performance and lifespan.

Avoid contaminants

Minimize exposure to contaminants that may interfere with the ion exchange process. Pre-treat the feed water if necessary to reduce the presence of substances that could negatively impact resin performance.

Prevent channeling

To prevent channeling (the formation of preferential flow paths through the resin bed), distribute the flow of the solution evenly through the resin column. This can be achieved through proper system design and maintenance.

Proper storage

Store ion exchange resin in a dry environment to prevent moisture absorption. Moisture can lead to degradation and reduce the resin's effectiveness.

Functional groups

Ion exchange resins are composed of a polymer matrix with specific functional groups attached to it. The nature of these functional groups determines whether the resin is cationic or anionic and, consequently, the type of ions it can exchange.

Ion exchange sites

The functional groups on the resin contain ion exchange sites. These sites are capable of attracting and holding ions of the opposite charge from the surrounding solution.

Native state or regenerated state

In its native state or after regeneration, the resin has certain ions associated with its functional groups. These ions are referred to as counterions. The counterions are typically in equilibrium with ions in the surrounding solution.

Ion exchange process

When the resin comes into contact with a solution containing ions of a different type, an ion exchange process begins. The functional groups on the resin release their counterions and attract ions from the solution.

For cation exchange resin

The resin releases cations (counterions) and exchanges them with cations from the solution. The exchanged cations are then held by the resin's functional groups.

For anion exchange resin

The resin releases anions (counterions) and exchanges them with anions from the solution. The exchanged anions are then held by the resin's functional groups.

Saturation and breakthrough

As the ion exchange process continues, the resin becomes saturated with the exchanged ions. Saturation refers to the point where the resin can no longer hold additional ions. Beyond this point, breakthrough occurs, and unexchanged ions may pass through the resin bed.

Continuous operation

In practical applications, ion exchange resins are often used in columns or beds through which the solution flows. This continuous flow allows for a sustained ion exchange process.

Applications

Ion exchange resins find applications in various industries, including water treatment, chemical processing, metal recovery, and purification of pharmaceuticals. The selective removal or exchange of specific ions makes these resins versatile in tailoring the composition of solutions.

Material of lon Exchange Resin

Polymer matrix

The backbone of the ion exchange resin is usually a polymer matrix. Commonly used polymers include polystyrene, polyacrylic, or polyacrylonitrile. The polymer provides the structural framework for the resin.

Functional groups

Functional groups are attached to the polymer matrix and determine the type of ions the resin can exchange. The choice of functional groups depends on the intended application. For example:

● Cation exchange resin: Contains functional groups with a negative charge, such as sulfonic acid (–so₃h) or carboxylic acid (–cooh).

● Anion exchange resin: Contains functional groups with a positive charge, such as quaternary ammonium (–n⁺r₄) or amine (–nr₂h).

Cross-linking agents

Cross-linking agents are added during the polymerization process to create a three-dimensional, cross-linked structure. Common cross-linking agents include divinylbenzene (dvb) and ethylene glycol dimethacrylate. The degree of cross-linking influences the resin's mechanical strength and swelling properties.

Counterions

Counterions are the ions associated with the functional groups in the resin when it is in its native or regenerated form. These counterions can be exchanged with other ions during the ion exchange process.

Water content

Ion exchange resins may contain a certain amount of water. The moisture content can impact the resin's performance, and proper drying is often part of the resin manufacturing process.

Can you Explain the Polymer Matrix in Ion Exchange Resin

Composition

The polymer matrix is typically made from cross-linked polymers, with polystyrene being a common choice. Other polymers such as polyacrylic or polyacrylonitrile may also be used, depending on the specific requirements of the resin.

Cross-linking

Cross-linking refers to the formation of chemical bonds between polymer chains, creating a three-dimensional network. Cross-linking agents, such as divinylbenzene (dvb) or ethylene glycol dimethacrylate, are added during the polymerization process to facilitate this cross-linking.

Stability and insolubility

The cross-linked structure imparts stability to the resin, making it resistant to chemical and physical changes. This stability ensures that the resin can withstand the rigors of various applications without degrading.

Insolubility in water

The cross-linked polymer matrix is insoluble in water. This property is crucial for the resin's functionality in water treatment applications, where it needs to maintain its structural integrity during ion exchange processes.

Mechanical strength

The degree of cross-linking influences the mechanical strength of the resin. Higher levels of cross-linking result in a more rigid structure, impacting the resin's ability to swell or shrink under different conditions.

Swelling properties

The polymer matrix can swell or shrink based on the presence of water or certain solvents. This property is important in ion exchange processes, as it allows the resin to accommodate changes in volume during ion exchange without disintegration.

Pore structure

The cross-linked polymer matrix often forms a porous structure. The size and distribution of these pores can impact the resin's ability to allow the flow of solutions through its bed, influencing the efficiency of ion exchange processes.

Selectivity

The polymer matrix, along with the attached functional groups, determines the selectivity of the ion exchange resin. The specific structure of the matrix contributes to the resin's ability to preferentially attract and exchange certain ions over others.

In Which Industries is Ion Exchange Resin Commonly Used

Water treatment

Ion exchange resin is extensively used in water treatment processes for both municipal and industrial water supplies. It is employed in water softening, removal of heavy metals, deionization, and purification of drinking water.

Chemical processing

The chemical industry utilizes ion exchange resin for purifying and separating chemicals, catalyzing reactions, and controlling ph levels in various processes.

Power generation

In power plants, ion exchange resin is used for the demineralization of water used in boiler feedwater. This helps prevent scale formation and corrosion in the steam generation system.

Pharmaceuticals

Ion exchange resin plays a crucial role in pharmaceutical manufacturing for the purification of drug formulations, removal of impurities, and separation of specific compounds.

Food and beverage

The food and beverage industry utilizes ion exchange resin for water softening, deionization, and removal of contaminants to meet quality standards in food and beverage production.

Electronics and semiconductor manufacturing

Ion exchange resin is used for ultra-pure water production in the electronics industry, ensuring the removal of impurities that could adversely affect semiconductor manufacturing processes.

Metal recovery

Industries involved in metal recovery, such as mining and metallurgy, use ion exchange resin for selectively extracting and concentrating valuable metals from solutions.

Nuclear power

Ion exchange resin is employed in nuclear power plants for the purification of cooling water and the treatment of radioactive waste.

Environmental remediation

Ion exchange resin is utilized in environmental applications for the removal of pollutants and contaminants from wastewater, contributing to environmental remediation efforts.

Agriculture

In agriculture, ion exchange resin can be used for soil conditioning, nutrient management, and water treatment in irrigation systems.

Oil and gas

Ion exchange resin may be used in the oil and gas industry for water treatment, especially in processes involving enhanced oil recovery or hydraulic fracturing.

Biotechnology

In biotechnological processes, ion exchange resin is employed for the purification of biomolecules, such as proteins and enzymes.

How Does Anion Exchange Resin Differ From Cation Exchange Resin

Type of ions exchanged

Cation exchange resin:

Exchanges positively charged ions (cations) with the surrounding solution. Common cations include hydrogen (h+), sodium (na+), and calcium (ca2+).

Anion exchange resin:

Exchanges negatively charged ions (anions) with the surrounding solution. Common anions include hydroxide (oh-), chloride (cl-), and sulfate (so4^2-).

Functional groups

Cation exchange resin:

Contains functional groups with a negative charge that can attract and exchange positively charged ions. Common functional groups include sulfonic acid (–so₃h) or carboxylic acid (–cooh).

Anion exchange resin:

Contains functional groups with a positive charge that can attract and exchange negatively charged ions. Common functional groups include quaternary ammonium (–n⁺r₄) or amine (–nr₂h).

Color coding

Cation exchange resin:

Often represented in blue color.

Anion exchange resin:

Often represented in brown or red color.

Selectivity

Cation exchange resin:

Selectively removes or exchanges cations from the solution. The resin prefers cations over anions.

Anion exchange resin:

Selectively removes or exchanges anions from the solution. The resin prefers anions over cations.

Common applications

Cation exchange resin:

Used in water softening, where it removes hardness ions like calcium and magnesium. Also employed in processes requiring selective extraction of metal cations.

Anion exchange resin:

Used in deionization processes to remove anions and produce highly purified water. Also utilized in applications where selective removal of acidic ions is required.

Regeneration process

Cation exchange resin:

Regenerated by treating it with a solution containing excess cations, replacing the adsorbed cations on the resin.

Anion exchange resin:

Regenerated by treating it with a solution containing excess anions, replacing the adsorbed anions on the resin.

Common materials

Cation exchange resin:

Commonly made from a polymer matrix with sulfonic acid or carboxylic acid functional groups.

Anion exchange resin:

Commonly made from a polymer matrix with quaternary ammonium or amine functional groups.

In practical applications, ion exchange systems may also utilize a combination of cation and anion exchange resins in mixed-bed configurations to achieve high-purity water production. The specific choice between cation and anion exchange resins depends on the desired outcome of the ion exchange process and the composition of the solution being treated.

What are the Advantages of Using Ion Exchange Resin in Water Treatment

Water softening

Ion exchange resin is highly effective in removing hardness ions, such as calcium and magnesium, which cause scale formation in pipes and appliances. Water softening improves the efficiency and lifespan of water heaters and appliances.

Deionization

Ion exchange resin can deionize water by selectively removing both cations and anions, producing highly purified water for industrial processes, laboratories, and other applications requiring ultra-pure water.

Heavy metal removal

Specific ion exchange resins are designed to remove heavy metals like lead, copper, and iron from water, addressing issues related to contamination and ensuring compliance with water quality standards.

Nitrate and sulfate removal

Ion exchange resins can be tailored to remove specific anions such as nitrate and sulfate, which can be problematic in drinking water and agricultural runoff.

Ph adjustment

Ion exchange resins can be employed for ph adjustment by selectively exchanging hydrogen ions (h+) or hydroxide ions (oh-) in solutions, aiding in the control of acidity or alkalinity.

Selective ion removal

The ability to selectively remove specific ions allows for tailored treatment strategies to address the unique composition of water in different locations or applications.

Regenerability

Many ion exchange resins are regenerable, meaning they can be recharged after reaching saturation. This regenerability enhances cost-effectiveness and sustainability in water treatment processes.

Versatility

Ion exchange resins are versatile and can be adapted to various water treatment applications, from large-scale municipal water treatment plants to small residential systems.

Efficient removal of contaminants

Ion exchange resin efficiently removes a wide range of contaminants, including radionuclides, organic pollutants, and various inorganic ions, contributing to the production of safe and clean water.

Consistent performance

Ion exchange resins provide consistent and reliable performance, ensuring the continued effectiveness of water treatment systems over time.

Taste and odor improvement

By removing certain ions responsible for taste and odor issues, ion exchange resin contributes to the improvement of the aesthetic qualities of drinking water.

Reduced scaling and fouling

Water treated with ion exchange resin is less prone to scale formation and fouling in industrial processes, reducing maintenance costs and downtime.

Environmental benefits

Ion exchange resin can contribute to environmentally friendly water treatment by reducing the need for harsh chemicals and minimizing the environmental impact of certain contaminants.

FAQ

As one of the leading ion exchange resin manufacturers and suppliers in China, we warmly welcome you to wholesale ion exchange resin in stock here from our factory. All customized products are with high quality and competitive price.

ion exchange resin for sugar decolorization, Vitamin C Bio Ceramics, ion exchange resin nitrate removal