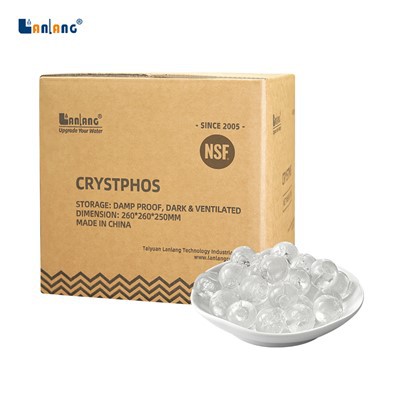

What is Crystphos Polyphosphate?

Crystphos polyphosphate is a type of polyphosphate compound, often used in various industrial and consumer applications. It is characterized by its crystalline form and is known for its effectiveness in water treatment processes. Crystphos polyphosphate helps in preventing scale formation and corrosion in water systems by sequestering metal ions. Additionally, it is used in detergents and cleaning agents to soften water and enhance cleaning efficiency. Its application extends to the agricultural sector as well, where it serves as a nutrient or a fertilizer additive. The versatility and effectiveness of crystphos polyphosphate make it an important chemical in improving the performance and longevity of water systems and in supporting various industrial processes.

Advantages of Crystphos Polyphosphate

Superior scale inhibition and corrosion control

Crystphos polyphosphate stands out for its exceptional ability to prevent the formation of scale and mitigate corrosion within water systems. This is particularly beneficial in industrial and municipal water treatment applications where hard water minerals can accumulate and damage pipes and machinery. By forming a thin protective layer on the surfaces of pipes and equipment, crystphos polyphosphate significantly reduces maintenance costs and extends the lifespan of infrastructure.

Enhanced water quality

The use of crystphos polyphosphate in water treatment processes plays a crucial role in improving water quality. It effectively sequesters metal ions such as iron and manganese, preventing discoloration, and unpleasant tastes or odors in drinking water. This sequestering action not only improves the aesthetic qualities of water but also makes it safer and more palatable for consumption.

Improved process efficiency in industrial applications

In industries where water plays a central role in production processes, crystphos polyphosphate offers significant advantages. Its ability to prevent scale and manage corrosion can lead to improved heat transfer efficiency in boilers and cooling systems. This efficiency is critical for energy conservation and reducing carbon footprints in manufacturing and production facilities.

Versatility and compatibility

Crystphos polyphosphate's chemical properties make it compatible with a wide range of water treatment systems and formulations. Its versatility is evident in its application across various industries, including food processing, where it acts as a sequestrant to improve the texture and stability of products.

Why Choose Us?

R&D

Invests heavily in R&D, continuously improving their product offerings and staying at the forefront of new material technology. dedication to innovation means customers can benefit from cutting-edge solutions.

Customization services

Provide customization services to meet specific customer requirements, ensuring that clients receive products that exactly fit their needs.

Experienced team

The company employs a team of experienced professionals with expertise in new material technologies, ensuring that their products and services are backed by deep knowledge and technical proficiency.

24h online service

We try and respond to all concerns within 24 hours and our teams are always at your disposal in case of any emergencies.

The Manufacturing Process of Crystphos Polyphosphate

Raw material preparation

The primary raw materials for making polyphosphates are phosphoric acid (h3po4) and a base such as sodium carbonate (na2co3) or sodium hydroxide (naoh). These materials are prepared and purified as needed to ensure the quality of the final product.

Mixing and reaction

The prepared raw materials are mixed in a reaction vessel. The specific ratio of phosphoric acid to the base depends on the desired polyphosphate chain length and properties. The mixture is heated to facilitate the reaction, where the base neutralizes the phosphoric acid, leading to the formation of sodium phosphate.

Polymerization

Upon further heating and under controlled conditions, the sodium phosphate undergoes a condensation reaction, where water molecules are eliminated, and long chains of polyphosphate are formed. This step is critical and needs to be carefully controlled to achieve the desired chain length and properties of the polyphosphate.

Crystallization

The polyphosphate solution can then be cooled, and the polyphosphate salts can crystallize out of the solution. The rate of cooling and the conditions during crystallization can affect the size and purity of the crystals.

Separation and washing

The crystallized polyphosphate is separated from the liquid by filtration or centrifugation. It is then washed to remove impurities and any unreacted starting materials.

Drying

The washed crystals are dried to remove any residual moisture. The drying process must be controlled to prevent any thermal degradation of the polyphosphate chains.

Milling and sizing

Once dried, the polyphosphate crystals might be milled to achieve a uniform particle size suitable for its intended application. The final product can then be packaged and stored.

Quality control

Throughout the manufacturing process, quality control measures are in place to ensure the final product meets the required specifications. This includes monitoring the chemical composition, chain length, solubility, and other properties of the polyphosphate.

Application of Crystphos Polyphosphate

Water treatment

Scale inhibition: Polyphosphates are effective at preventing scale formation in pipes and equipment by sequestering metal ions such as calcium and magnesium, which are responsible for hard water scale.

Corrosion control: By forming a thin protective layer on the inner surfaces of pipes, polyphosphates can help reduce corrosion in plumbing systems and water heaters.

Food and beverage industry

Preservation: Polyphosphates are used as preservatives in food products because they can inhibit the growth of bacteria and fungi. They also help in retaining moisture in processed foods, improving texture and shelf life.

Emulsification and stabilization: In processed meats, polyphosphates are added to improve water retention, texture, and stability. They act as emulsifiers, helping to disperse fats and oils evenly.

Agriculture

Fertilizers: Some polyphosphates are used as liquid fertilizers, providing plants with a source of phosphorus that is gradually made available as the polyphosphate slowly hydrolyzes to orthophosphate, which is readily absorbed by plants.

Industrial applications

Detergents and cleaners: Polyphosphates can sequester hardness ions, enhancing the effectiveness of detergents and cleaning agents by preventing the formation of insoluble salts.

Metal treatment and plating: In metal finishing and plating processes, polyphosphates are used to treat the metal surfaces, improving paint adhesion and corrosion resistance.

Oil and gas industry

Drilling mud additives: Polyphosphates can be used in drilling muds to control the viscosity and to stabilize the mud by sequestering divalent cations.

Textile and paper industries

Water softening: In textile and paper manufacturing, water hardness can affect the process and quality of the final product. Polyphosphates are added to the water to sequester calcium and magnesium ions, softening the water.

Potable water systems

Lead and copper control: In potable water systems, polyphosphates can help reduce the levels of lead and copper that leach from pipes by forming protective coatings on the pipe interiors.

Things to Note When Using Crystphos Polyphosphate

Concentration and dosage

Correct dosage: Using the correct amount of polyphosphate is crucial for achieving the desired effect without wasting material or causing unintended side effects. Overuse can lead to issues like excessive sodium in water systems or adverse effects in food products.

Application specific: The optimal concentration can vary widely depending on the application, such as scale prevention in water systems versus food preservation.

Water chemistry

For applications involving water treatment, the chemistry of the water, including ph, hardness, and the presence of other ions, significantly affects the performance of polyphosphates. Testing and adjusting the water chemistry may be necessary to ensure the effectiveness of polyphosphate treatment.

Temperature considerations

Polyphosphate effectiveness can vary with temperature. In some cases, higher temperatures can increase the rate of hydrolysis, converting polyphosphates back into orthophosphates, which may not provide the desired functionality.

Handling and storage

Polyphosphates should be handled with care, following material safety data sheet (msds) guidelines to avoid exposure-related health issues. Proper storage is necessary to prevent moisture uptake, which can lead to clumping or degradation of the polyphosphate.

Compatibility with other chemicals

In systems where multiple chemical agents are used, it's important to consider the compatibility of polyphosphates with these chemicals. Incompatibilities can reduce effectiveness or even produce harmful byproducts.

Environmental impact

Consideration of the environmental impact of polyphosphate use is essential. Misuse or overuse can contribute to eutrophication in water bodies, leading to algal blooms and oxygen depletion, which harm aquatic ecosystems.

How to Maintain Crystphos Polyphosphate

Storage conditions

Ensure proper storage conditions as specified by the manufacturer. This may include temperature, humidity, and compatibility with other substances.

Regular inspections

Periodically inspect the storage containers or systems to ensure they are in good condition and free from leaks or damage.

Handling procedures

Follow recommended handling procedures to avoid contamination or degradation of the product. This may include using appropriate equipment, protective gear, and handling practices.

Testing and monitoring

If applicable, conduct regular testing or monitoring of the product's properties to ensure it meets the required specifications. This may involve analytical techniques or on-site testing, depending on the nature of the product.

Water treatment

Polyphosphates are used in water treatment processes to inhibit scale formation and control water hardness. They can sequester metal ions and prevent the precipitation of minerals that can lead to scale buildup in pipes and equipment.

Food additives

In the food industry, polyphosphates are used as additives for various purposes, including improving the texture of processed meats, enhancing moisture retention, and acting as a leavening agent in baked goods.

Detergency

Polyphosphates are added to detergents and cleaning products to enhance their effectiveness. They help in preventing the deposition of minerals on surfaces, making cleaning more efficient.

Corrosion inhibition

Some polyphosphates can act as corrosion inhibitors, protecting metal surfaces from degradation caused by corrosive substances in industrial processes.

Cooling water treatment

Polyphosphates can be used in cooling water systems to prevent scale formation and corrosion in heat exchange equipment.

What are the Recommended Storage Conditions for Crystphos Polyphosphate

Temperature: Store crystphos polyphosphate in a cool, dry place. Avoid exposure to extreme temperatures, both high and low. Extremes in temperature can affect the stability and properties of the substance.

Ventilation: Ensure adequate ventilation in the storage area to prevent the accumulation of vapors or gases. This is particularly important if crystphos polyphosphate releases any fumes.

Containers: Store crystphos polyphosphate in its original, tightly sealed containers. Use containers made of materials compatible with the substance. Avoid using containers that may react with or be degraded by the product.

Incompatibilities: Keep crystphos polyphosphate away from incompatible materials. The manufacturer's guidelines or sds should provide information on substances that may react adversely with crystphos polyphosphate.

Moisture: Prevent exposure to moisture or humidity, as this can lead to clumping or caking of the product. Moisture can also compromise the effectiveness of some chemical substances.

Labeling: Ensure that containers are properly labeled with the product name, hazard information, and any specific storage instructions. This helps in proper identification and handling.

Separation: Store crystphos polyphosphate away from other incompatible chemicals to prevent cross-contamination.

Can Crystphos Polyphosphate be Used in Food Applications

Food additives, including phosphates and polyphosphates, are subject to regulations and guidelines set by food safety authorities in different countries. These regulations often include specifications regarding acceptable types and concentrations of additives, as well as any labeling requirements.

Contact the manufacturer

Reach out to the manufacturer of crystphos polyphosphate and inquire about its suitability for use in food applications. Manufacturers typically provide detailed information on the intended uses of their products.

Compliance with regulations

Check whether crystphos polyphosphate complies with local and international regulations for food additives. This may involve consulting with food safety authorities or regulatory agencies.

Review safety data sheet

Examine the product's safety data sheet for information on composition, potential hazards, and any restrictions or recommendations regarding its use in food.

Application specifics

If the manufacturer indicates that the product can be used in food applications, ensure that you follow any recommended dosage levels and application guidelines.

What Safety Precautions Should be Taken When Handling Crystphos Polyphosphate

Personal protective equipment

Wear appropriate ppe, including gloves, safety goggles or a face shield, and protective clothing, to minimize skin and eye contact with the substance.

Ventilation

Use the product in a well-ventilated area to minimize exposure to vapors or fumes. If necessary, use local exhaust ventilation systems.

Avoid ingestion

Do not eat, drink, or smoke while handling crystphos polyphosphate. Avoid any form of ingestion, as the substance may pose health risks if swallowed.

Avoid inhalation

Prevent inhalation of dust, vapors, or mists. If airborne particles are a concern, wear a suitable respiratory protective device.

Storage and handling

Follow the recommended storage conditions provided by the manufacturer. Handle containers with care, and avoid damage that may lead to leaks or spills.

First aid measures

Familiarize yourself with first aid measures in case of exposure. Have access to an emergency eyewash station and a safety shower.

Emergency procedures

Be aware of emergency procedures in case of spills, leaks, or accidents. This may include evacuation routes, emergency contacts, and procedures for containing and cleaning up spills.

Chemical compatibility

Be aware of the chemical compatibility of crystphos polyphosphate with other substances to avoid potentially hazardous reactions.

Waste disposal

Dispose of crystphos polyphosphate in accordance with local regulations. Follow proper waste disposal procedures, and do not discharge into water bodies or the environment.

Chemical composition

The specific chemicals present in each phosphate-based compound can influence their properties and effectiveness in various applications.

Functionality

Different phosphate compounds may have specific functions, such as acting as sequestrants, scale inhibitors, corrosion inhibitors, or as components in detergents and cleaning products.

Solubility

Solubility in water is a crucial factor for many phosphate-based compounds, especially those used in water treatment applications. Solubility can impact the compound's effectiveness and ease of use.

Ph stability

The stability of phosphate compounds under different ph conditions can vary. Some compounds may be more effective in acidic environments, while others perform better in alkaline conditions.

Environmental impact

Considerations regarding the environmental impact, biodegradability, and eco-friendliness of phosphate compounds are important, especially in industries where sustainability is a priority.

What Industries Commonly Use Crystphos Polyphosphate in Their Processes

Water treatment

Polyphosphates are often used in water treatment processes to inhibit scale formation, control water hardness, and prevent corrosion in pipes and equipment.

Detergent and cleaning products

Polyphosphates can be found in detergents and cleaning products, where they function to enhance cleaning efficiency and prevent the deposition of minerals on surfaces.

Food industry

Some polyphosphates are used as food additives in the food processing industry. They may be employed to improve the texture of processed meats, act as a leavening agent in baked goods, or enhance moisture retention in certain food products.

Metal processing

In metal processing industries, polyphosphates can be used as corrosion inhibitors to protect metal surfaces from corrosion.

Cooling water systems

Polyphosphates are utilized in cooling water systems to prevent scale formation and corrosion in heat exchange equipment.

Textile industry

Certain industries, such as textiles, may use polyphosphates for specific applications related to the processing of fabrics and materials.

Is Crystphos Polyphosphate Compatible With Other Chemicals or Additives

Review product documentation

Examine the product's safety data sheet (sds) and any other documentation provided by the manufacturer. This documentation may include information on chemical compatibility, stability, and recommended conditions for use.

Conduct compatibility tests

If needed, perform compatibility tests in a controlled environment to assess how crystphos polyphosphate reacts when combined with other substances. This can be particularly important in industrial processes where multiple chemicals are used.

Consider application conditions

Take into account the specific conditions of your application, including temperature, ph, and concentrations of various substances. These factors can influence the compatibility of crystphos polyphosphate with other chemicals.

What is the Recommended Dosage of Crystphos Polyphosphate in Different Applications

01

Conduct water analysis

Perform a thorough analysis of the water that will be treated. Factors such as water hardness, ph, and the presence of specific contaminants can influence the required dosage.

02

Consider application type

Different applications may have varying dosage requirements. For example, the dosage needed for water treatment in an industrial setting may differ from that required for a household application.

03

Trial and monitoring

In some cases, it may be advisable to start with a lower dosage and gradually increase it while monitoring the treatment effectiveness. This approach allows for adjustments based on actual performance.

04

Adherence to regulations

Ensure that the dosage of crystphos polyphosphate complies with local regulations and standards, especially in applications related to water treatment or food processing.

Can Crystphos Polyphosphate be Used in Conjunction With Other Water Treatment Chemicals

Conduct compatibility tests

If needed, perform compatibility tests in a controlled environment to assess how crystphos polyphosphate interacts with other water treatment chemicals. This can help identify any potential issues before large-scale use.

Consider application conditions

Take into account the specific conditions of your water treatment application, including temperature, ph, and the concentrations of various substances. These factors can influence the compatibility of crystphos polyphosphate with other chemicals.

Dosage considerations

Ensure that the combined dosage of crystphos polyphosphate and other water treatment chemicals falls within the recommended ranges provided by the manufacturers. Overdosing or improper mixing may lead to undesirable effects.

Adherence to regulations

Verify that the combined use of crystphos polyphosphate and other water treatment chemicals complies with local regulations and industry standards.

How Stable is Crystphos Polyphosphate Under Various Temperature and Ph Conditions

Conduct stability tests

If necessary, conduct stability tests in a controlled environment to assess how crystphos polyphosphate performs under varying temperature and ph conditions. This can be particularly important in industrial processes where these factors may fluctuate.

Consider application conditions

Take into account the specific conditions of your application. For example, if crystphos polyphosphate is used in water treatment, consider the typical temperature and ph range of the water being treated.

FAQ

As one of the leading crystphos polyphosphate manufacturers and suppliers in China, we warmly welcome you to wholesale crystphos polyphosphate in stock here from our factory. All customized products are with high quality and competitive price.

groundwater treatment ion exchange resin, ceramic ball for safe consumption, well drilling resin