Professional Team

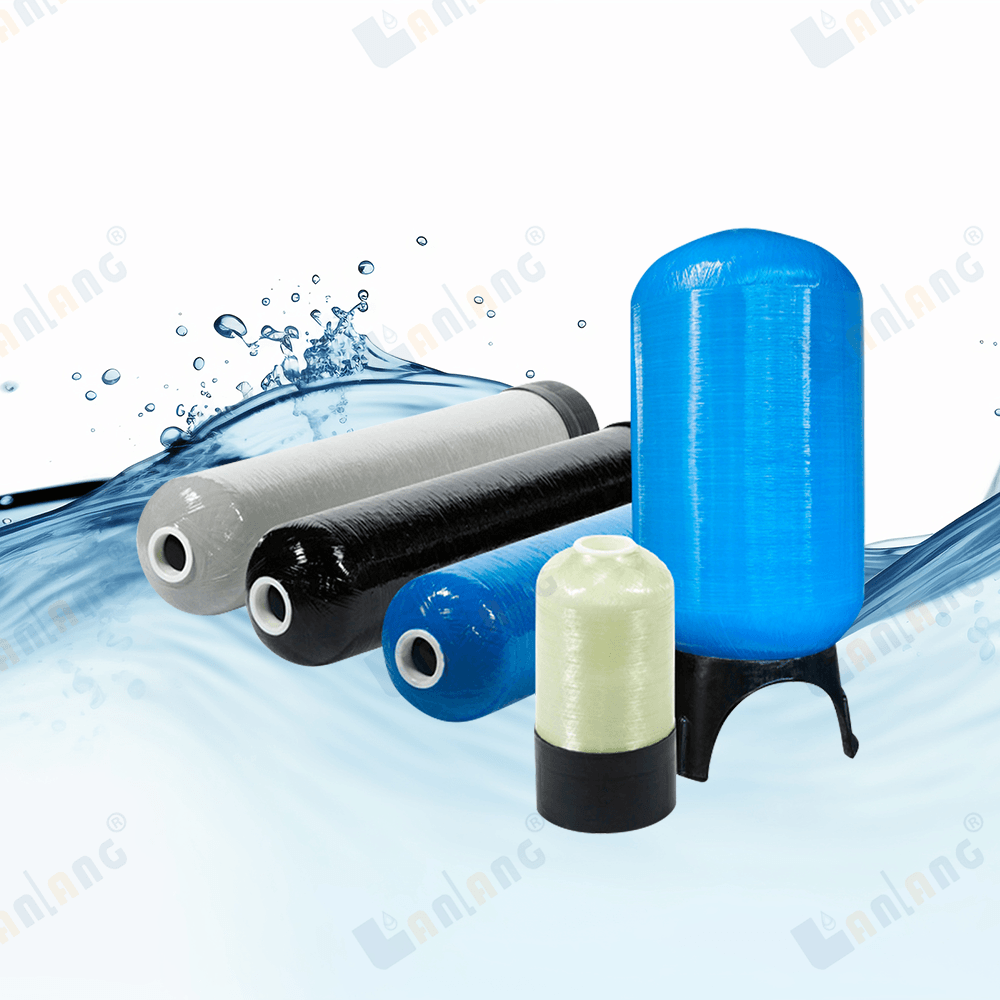

Glass fiber reinforced plastic storage tank is a glass steel product, which is superior to stainless steel products both in performance and in service life. Due to the flexibility of FRP storage tank design, it has been applied in the chemical industry, environmental protection industry, food industry and so on, and the market area is also gradually expanding. What are the physical properties of FRP tanks? The quality of FRP storage tank is very light but mild is very high, its bending and compression strength are very high, and its corrosion resistance is also very good, often used in the chemical industry, it has a high resistance to the atmosphere, water and some high concentration of acid and alkali, and now it has begun to replace steel carbon, non-ferrous metals and other products. It caused a lot of impact on them. Due to the large design flexibility of FRP storage tanks and excellent structural performance of tank walls, fiber-wound FRP can change the resin system or reinforcement material to high-speed physical and chemical properties of FRP storage tanks and non-standard devices to meet the needs of different media and working conditions.

Precautions for winding FRP storage tanks

Glass fiber reinforced plastic storage tank is a kind of glass fiber reinforced plastic products, which is mainly made of glass fiber as reinforcement agent, resin as adhesive by microcomputer control machine winding and manufacturing of new composite materials. The following describes several precautions for FRP storage tanks when winding:

1. In the winding process of FRP storage tank, appropriately increasing the number of fiber strands and reducing the number of winding layers is one of the measures to improve the production efficiency of FRP storage tank. However, in the application should be considered comprehensively, can not blindly pursue production efficiency. When the number of fiber strands increases, the phenomenon of "overhead" at the intersection of winding lines and the cutting point of polar holes will be intensified. Pores are formed between the fibers in the overhead part and the lining. When the container is pressurized, the aluminum lining can not withstand the pressure and will be squeezed into the overhead part, which seriously affects the fatigue performance of the container. When the number of fiber strands increases, the number of longitudinal winding layers decreases correspondingly, and the number of envelope circle diameter will also decrease, so that the fiber can not be evenly distributed in the head, resulting in a decrease in head strength. Therefore, the measure of increasing shares and reducing layers should be carefully adopted. Improper application will result in a decline in product quality.

2. Tension control of decreasing layer by layer during winding

An important prerequisite for fiber wound FRP tank manufacturers to obtain high strength is to make each bundle of fibers subject to uniform tension, that is, when the tank is subjected to internal pressure, all fibers are stressed at the same time. If the fiber is loose and tight, all the fibers cannot be stressed at the same time, which will affect the strength of the fiber. The size of the tension also directly affects the rubber content, specific gravity and porosity of the product. The unreasonable tension system will cause the fiber to wrinkle and the lining to yield, which will seriously affect the strength and fatigue performance of the container. The winding tension should decrease layer by layer. This is because a layer of fiber wrapped after the tension will cause the first layer of fiber wrapped together with the lining compression deformation, so that the inner fiber becomes loose. If the constant tension system is used, the fiber on the FRP tank manufacturer will be in a loose and tight state, so that the initial stress of the internal and external fibers is very different, and the fiber can not be evenly stressed at the same time when the container is pressurized. In severe cases, the inner fiber can produce wrinkles, lining bubbling, deformation and other yield states. This will greatly reduce the strength and fatigue properties of the container.

After using the tension system of decreasing layer by layer, although the fiber wrapped after the fiber wrapped on the first still has a cutting effect, but because the tension is smaller, it is the same as the tension after the first layer is cut, so that all the wound layers can be guaranteed to have the same deformation and initial tension from inside to outside. When the container is pressed, the fiber can be stressed at the same time, so that the strength of the container is improved.