Selective removal resins are highly specialized materials used in a wide range of industries for targeted separation and purification processes. As a supplier of selective removal resin, I often encounter the question: Does selective removal resin require a curing agent? In this blog post, I will delve into this topic, exploring the nature of selective removal resins, their applications, and the role of curing agents.

Understanding Selective Removal Resins

Selective removal resins are designed to selectively adsorb specific ions or molecules from a solution. They work based on the principle of ion exchange or adsorption, where the resin has a high affinity for certain target species. These resins are commonly used in water treatment, mining, chemical processing, and other industries to remove contaminants or recover valuable substances.

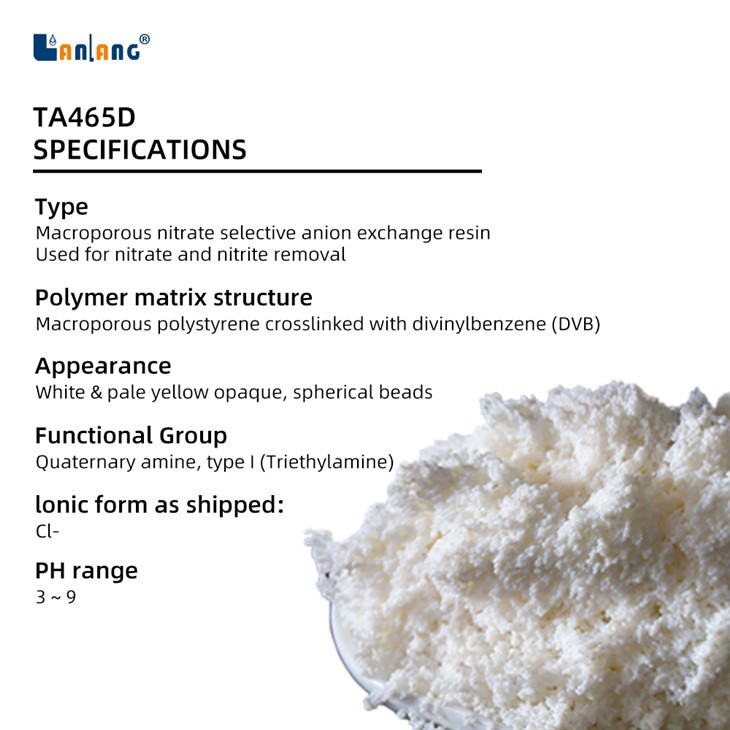

For example, Selective Removal Resin for Nitrate Removal is specifically engineered to remove nitrate ions from water. Nitrate contamination in water can pose significant health risks, especially for infants and pregnant women. By using this type of resin, water treatment facilities can effectively reduce nitrate levels to safe standards.

Another application is Selective Removal Resin for Uranium Extraction. In the mining industry, these resins are used to extract uranium from ore solutions. They selectively bind to uranium ions, allowing for efficient separation and recovery of this valuable resource.

Similarly, Selective Removal Resin for Fluorine Removal is used to remove fluoride ions from water. Excessive fluoride in drinking water can lead to dental and skeletal fluorosis. The selective removal resin provides a reliable solution for reducing fluoride levels to acceptable limits.

The Role of Curing Agents

Curing agents are substances that are used to harden or set a material. In the context of resins, curing agents initiate a chemical reaction that causes the resin to cross - link and form a solid, stable structure. However, not all resins require curing agents.

Most selective removal resins do not require a curing agent. These resins are typically supplied in a ready - to - use form. They are pre - manufactured with a specific chemical structure that allows them to perform their selective adsorption function. The resin beads are designed to be porous, providing a large surface area for ion exchange or adsorption to occur.

The absence of a curing agent simplifies the application process. Users can directly load the resin into a column or a reactor without the need for additional mixing or curing steps. This makes selective removal resins a convenient and cost - effective solution for many applications.

However, there are some special cases where a curing agent might be involved. For example, in certain custom - made resin systems or in applications where the resin needs to be embedded in a matrix, a curing agent could be used. In these situations, the curing agent helps to bond the resin to the matrix material, providing additional mechanical stability. But these are exceptions rather than the norm.

Advantages of Selective Removal Resins without Curing Agents

The fact that most selective removal resins do not require curing agents offers several advantages:

Ease of Use

As mentioned earlier, the absence of a curing agent simplifies the installation and operation process. Users do not need to worry about the proper mixing ratio of the resin and the curing agent, or the curing time and conditions. This reduces the risk of errors during the application process and ensures consistent performance.

Cost - Effectiveness

Curing agents can add to the cost of a resin system. By eliminating the need for a curing agent, the overall cost of the selective removal resin is reduced. This is especially important for large - scale applications where cost is a major consideration.

Flexibility

Selective removal resins without curing agents can be easily replaced or regenerated. When the resin reaches the end of its adsorption capacity, it can be removed from the system, regenerated using a suitable solution, and then reused. This recyclability makes the resin a more sustainable option.

Considerations for Selective Removal Resin Applications

When using selective removal resins, there are several factors to consider:

Selectivity

It is crucial to choose a resin with the appropriate selectivity for the target species. Different resins have different affinities for various ions or molecules. For example, a resin designed for nitrate removal may not be effective for removing other contaminants. Therefore, a thorough understanding of the composition of the solution and the target species is necessary.

Capacity

The adsorption capacity of the resin is another important factor. This refers to the amount of the target species that the resin can adsorb before it needs to be regenerated. Higher capacity resins can operate for longer periods between regenerations, reducing operating costs.

Regeneration

Proper regeneration of the resin is essential for maintaining its performance. The regeneration process involves removing the adsorbed species from the resin and restoring its adsorption capacity. The choice of regeneration solution and the regeneration conditions can significantly affect the efficiency of the process.

Conclusion

In conclusion, most selective removal resins do not require a curing agent. These resins are designed to be ready - to - use, offering ease of use, cost - effectiveness, and flexibility. However, in some special cases, a curing agent may be used for specific applications.

As a supplier of selective removal resins, we are committed to providing high - quality products that meet the diverse needs of our customers. Whether you are in the water treatment, mining, or chemical processing industry, our selective removal resins can offer a reliable solution for your separation and purification requirements.

If you are interested in learning more about our selective removal resins or would like to discuss your specific application, please feel free to contact us for procurement and further negotiation. We look forward to working with you to find the best resin solution for your needs.

References

- Ion Exchange Resins: Principles and Applications, CRC Press.

- Handbook of Water and Wastewater Treatment Technologies, Wiley.