Common causes of ion exchange resin breakage

poor manufacturing quality

In the process of resin manufacturing, due to improper maintenance of process parameters, some or a large number of resin particles will be cracked or broken, which is characterized by low crushing strength of resin particles and low round rate after grinding.

Freeze

Resin particles contain a lot of water inside, in the temperature below zero storage or transportation, the water will freeze, the volume expansion, resulting in the collapse of resin particles. A large number of cracks can be seen in the frozen resin under the microscope, and serious breakage will occur in the short term after use. In order to prevent the resin from freezing, the resin should be kept at 5-40 ° C to avoid transportation during the freezing period.

Dry

When the resin particles are exposed to air, they gradually lose their internal moisture, and the resin particles shrink smaller. When the dry resin is immersed in water, it will quickly absorb water, and the particle size will expand, resulting in the cracking of the resin and crushing. For this reason, the resin should be kept sealed during storage and transportation to prevent drying. For the resin that has been air-dried, it should first be immersed in saturated salt water, the concentration of ions in the solution is used to inhibit the expansion of the resin particles, and then gradually diluted with water to reduce the cracking and crushing of the resin.

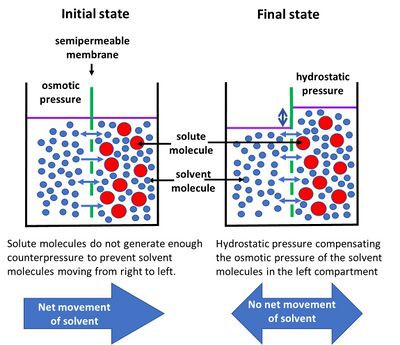

Influence of osmotic pressure

In the normal operation of the resin, during the failure process, the resin particles will produce internal stress of expansion or contraction. In the long-term use of resin, repeated expansion and contraction is the main reason for the crack or crushing of resin particles. The rate of resin expansion and contraction depends on the rate of resin transformation, which in turn depends on the concentration of salts in the water and the flow rate. When the gel type resin is used for natural water chemical demineralization, the flow rate is generally only 40m/h, and when it is used for condensate demineralization, the flow rate is generally only 60m/h.

Because of the strong skeleton structure and large porosity, the large-porosity resin can withstand a large transition speed, and the flow rate of condensate can reach 100m/h. For the special fast mixing bed resin, the flow rate can be 120m/h.