Mixed bed regeneration is a common process in water treatment that uses a combination of cation and anion exchange resins to remove dissolved impurities from water. Over time, these resins become exhausted and need to be regenerated to maintain their effectiveness. One of the most important steps in the regeneration process is backwashing, which involves flushing the resin bed with water to remove any debris or particulate matter that may have accumulated.

However, when backwashing mixed beds, it is important to ensure that the resins remain separated during the process. If the cation and anion resins mix together, they can form a salt bridge which can prevent the proper regeneration of the resins. One way to prevent this mixing is through the process of backwash layering.

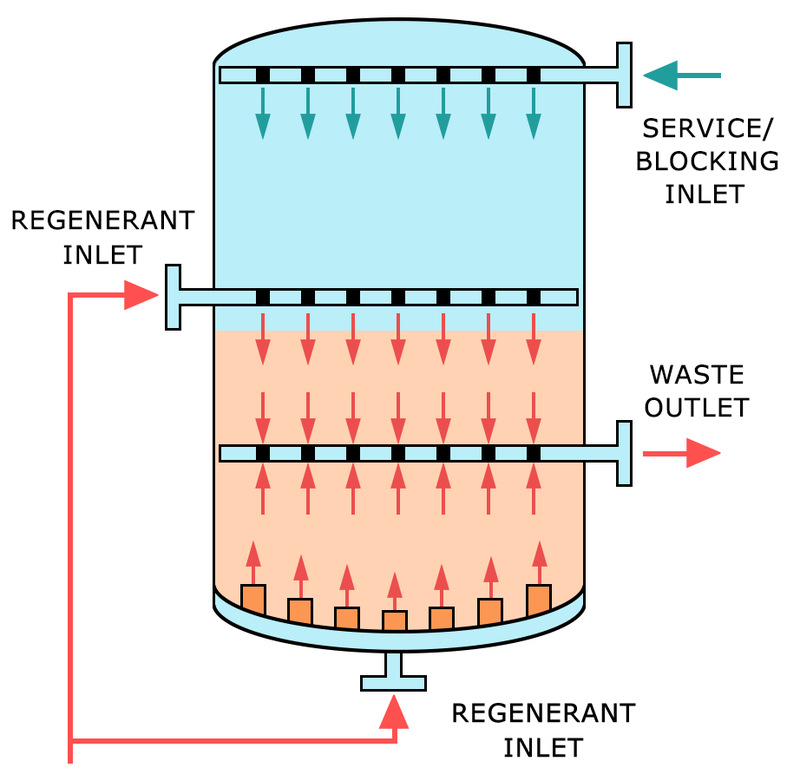

Backwash layering involves creating separate layers of cation and anion resins within the mixed bed. During the backwashing process, the water flow is carefully controlled to ensure that it passes through each layer separately, rather than mixing the resins together. This helps to prevent the formation of salt bridges and ensures that both resins are properly regenerated.

In addition to preventing salt bridges, backwash layering also helps to ensure even distribution of the backwash water throughout the entire resin bed. This is important because if the water flow is not evenly distributed, certain areas of the resin bed may become overly compressed or disturbed, which can lead to poor regeneration efficiency.

Overall, backwash layering is an important technique for ensuring the proper regeneration of mixed bed resin systems. By carefully controlling the flow of water during the backwashing process, operators can prevent salt bridges and ensure that both cation and anion resins are effectively regenerated. With careful attention to detail, mixed bed resin systems can continue to provide high-quality water treatment for many years.