Wet metallurgical processes are used to extract metals from ores or other sources by using solutions of chemical reagents. The efficiency of this process depends on the nature and concentration of the reagents used. Therefore, it is essential to ensure the availability of high-quality reagents to ensure optimal extraction efficiency. One such high-quality reagent used in wet metallurgy is ion exchange resins.

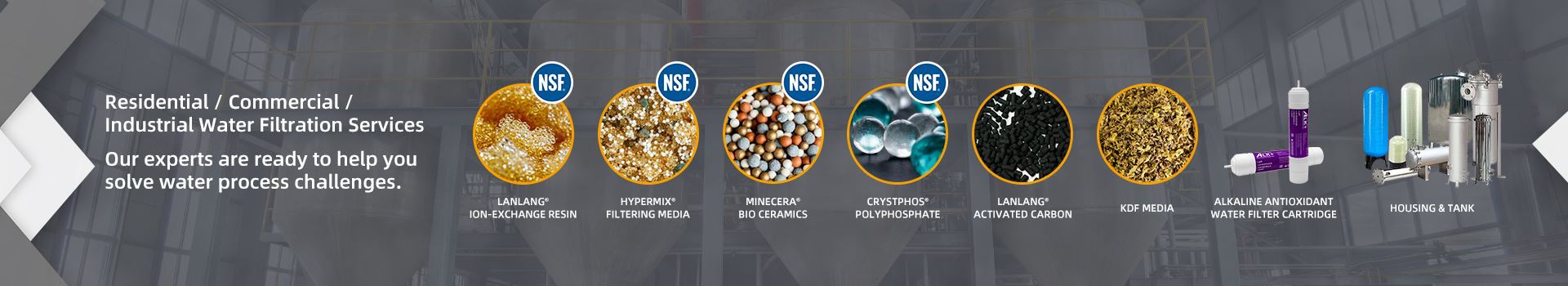

Ion exchange resin is a highly specialized material with a high exchange capacity for ions. The resins can be used for both cation and anion exchange, making them highly versatile in their application. In this article, we will explore the various applications of ion exchange resins in wet metallurgy.

Applications of Ion Exchange Resins in Wet Metallurgy

1. Separation of metal ions

Ion exchange resins are used for the separation of metal ions from mineral concentrates or leach solutions. The resins use their high exchange capacity to selectively capture the desired metal ions, leaving behind unwanted impurities.

2. Purification of leach solutions

Leach solutions are commonly used in hydrometallurgical processes to extract metals from ores. However, these solutions may contain impurities that can interfere with the extraction efficiency. Ion exchange resins can be used to remove these impurities and ensure a pure leach solution for optimal extraction efficiency.

3. Recovery of metal ions

Ion exchange resins can also be used for the recovery of metal ions from waste streams. The resins selectively adsorb the metal ions, leaving behind a purified waste stream. The recovered metal ions can be reused in the metallurgical process, reducing the need for new metal sources.

4. Refining of metals

Ion exchange resins can be used for the refining of metal products. The resins can remove impurities from the metal products, improving their physical and chemical properties. This improves the quality of the metal products and ensures they meet industrial standards.

5. Recovery of rare earth elements

Rare earth elements are used in various high-tech applications such as renewable energy technologies, electronics, and magnets. Ion exchange resins have been successfully used for rare earth element recovery from various sources such as monazite sands, ion-adsorption clays, and phosphogypsum waste.

Conclusion

Ion exchange resins are critical reagents in wet metallurgy processes. Their versatility and high exchange capacity make them suitable for various applications such as separation of metal ions, purification of leach solutions, recovery of metal ions, refining of metals, and recovery of rare earth elements. Through their use, optimal extraction efficiency can be achieved, ensuring the availability of high-quality metal products for various industrial applications.