As a supplier of Catalyst Resin, I often encounter inquiries regarding the curing time of this remarkable product. Understanding the curing time is crucial for users as it directly impacts the efficiency and quality of their processes. In this blog, I will delve into the factors that influence the curing time of Catalyst Resin and provide some practical insights to help you optimize your operations.

Understanding Catalyst Resin

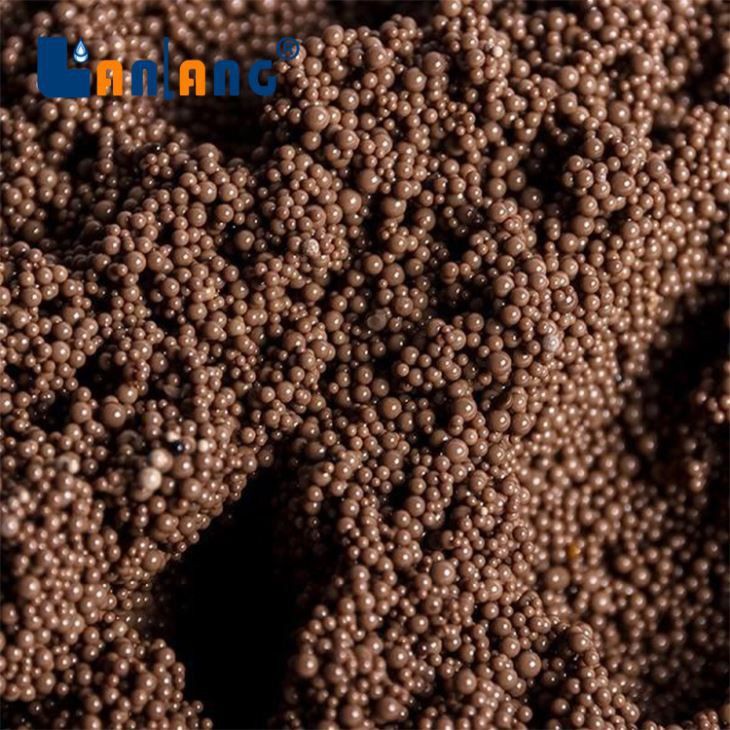

Catalyst Resin is a type of ion exchange resin that is widely used in various industrial applications, such as biodiesel esterification, chemical synthesis, and water treatment. It acts as a catalyst to accelerate chemical reactions by providing a large surface area for reactants to interact. Our Catalyst Resin Series offers a range of high-quality products tailored to different needs, ensuring optimal performance in diverse environments.

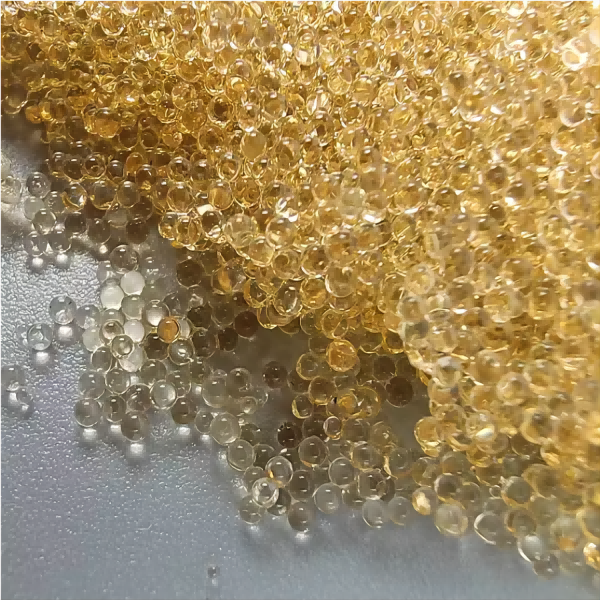

One of our popular products is the TY CS710 Gel Type Strong Acid Cation Exchange Resin. This resin is specifically designed for applications that require strong acid cation exchange capabilities. It has excellent physical and chemical stability, high exchange capacity, and good mechanical strength, making it an ideal choice for many industrial processes.

Factors Affecting the Curing Time of Catalyst Resin

The curing time of Catalyst Resin can vary significantly depending on several factors. Here are some of the key factors that you need to consider:

1. Resin Type and Composition

Different types of Catalyst Resin have different curing characteristics. For example, gel-type resins generally have a longer curing time compared to macroporous resins. This is because gel-type resins have a more compact structure, which restricts the diffusion of reactants and curing agents. Additionally, the composition of the resin, such as the type and amount of functional groups, can also affect the curing time.

2. Curing Agent and Its Concentration

The choice of curing agent and its concentration play a crucial role in determining the curing time. Different curing agents have different reaction rates and activation energies, which can significantly impact the curing process. Generally, a higher concentration of curing agent can accelerate the curing process, but it may also lead to a shorter pot life and increased brittleness of the cured resin.

3. Temperature and Humidity

Temperature and humidity are important environmental factors that can affect the curing time of Catalyst Resin. Higher temperatures generally accelerate the curing process by increasing the reaction rate. However, excessive temperatures can also cause the resin to degrade or develop cracks. Humidity can also have an impact on the curing process, especially for resins that are sensitive to moisture. High humidity can slow down the curing process and may even cause the resin to absorb moisture, leading to poor performance.

4. Mixing Ratio and Uniformity

The mixing ratio of the resin and curing agent is critical for achieving proper curing. An incorrect mixing ratio can result in incomplete curing or over-curing, both of which can affect the performance of the resin. Additionally, the uniformity of the mixing is also important. If the resin and curing agent are not mixed thoroughly, there may be areas of under-cured or over-cured resin, which can lead to inconsistent performance.

Determining the Optimal Curing Time

To determine the optimal curing time for your specific application, it is recommended to conduct some preliminary tests. Here are the steps you can follow:

1. Select the Appropriate Resin and Curing Agent

Based on your application requirements, choose the right type of Catalyst Resin and curing agent. Consult with our technical experts if you are unsure about which product to use.

2. Prepare the Samples

Prepare a series of samples with different curing times by varying the factors mentioned above, such as temperature, humidity, and mixing ratio. Make sure to label each sample clearly.

3. Conduct the Tests

Perform the necessary tests on the samples to evaluate their performance, such as hardness, chemical resistance, and mechanical strength. Compare the results of the different samples to determine the optimal curing time.

4. Monitor the Curing Process

During the curing process, monitor the samples regularly to observe any changes in their appearance and properties. This can help you identify any potential issues and make adjustments if necessary.

Practical Tips for Optimizing the Curing Process

Here are some practical tips to help you optimize the curing process of Catalyst Resin:

1. Follow the Manufacturer's Instructions

Always follow the manufacturer's instructions regarding the mixing ratio, curing time, and other processing parameters. This will ensure that you achieve the best results and avoid any potential problems.

2. Control the Environmental Conditions

Maintain a stable temperature and humidity environment during the curing process. Use a temperature-controlled oven or a humidity chamber if necessary. This will help to ensure consistent curing and improve the performance of the resin.

3. Use Proper Mixing Equipment

Use a high-quality mixing equipment to ensure thorough mixing of the resin and curing agent. This will help to eliminate any air bubbles and ensure uniform distribution of the curing agent throughout the resin.

4. Allow Sufficient Curing Time

Do not rush the curing process. Allow sufficient time for the resin to fully cure before using it in your application. This will ensure that the resin has reached its maximum strength and performance.

Applications of Catalyst Resin and the Importance of Curing Time

Catalyst Resin has a wide range of applications in various industries. One of the most common applications is in biodiesel esterification. Our Catalyst Resin for Biodiesel Esterification is specifically designed to catalyze the reaction between triglycerides and alcohol to produce biodiesel. In this application, the curing time of the resin is crucial for ensuring the efficiency and quality of the biodiesel production process.

In chemical synthesis, Catalyst Resin is used to catalyze various chemical reactions, such as esterification, hydrolysis, and alkylation. The curing time of the resin can affect the reaction rate and selectivity, which in turn can impact the yield and quality of the final product.

In water treatment, Catalyst Resin is used to remove impurities and contaminants from water. The curing time of the resin can affect its ion exchange capacity and regeneration efficiency, which are important factors for ensuring the effectiveness of the water treatment process.

Conclusion

In conclusion, the curing time of Catalyst Resin is a critical factor that can significantly impact the performance and quality of your industrial processes. By understanding the factors that affect the curing time and following the practical tips provided in this blog, you can optimize the curing process and achieve the best results.

If you have any further questions or need more information about our Catalyst Resin products, please do not hesitate to contact us. We are always ready to assist you with your procurement needs and provide you with the best solutions for your applications.

References

- Smith, J. (2018). Ion Exchange Resins: Principles and Applications. Wiley.

- Jones, A. (2019). Catalysis in Industrial Processes. Elsevier.

- Brown, R. (2020). Biodiesel Production: A Comprehensive Guide. Springer.