Yo, what's up! I'm a supplier of RO membranes, and today I wanna chat about the super important role these membranes play in electronics manufacturing.

First off, let's get a basic understanding of what an RO membrane is. RO stands for Reverse Osmosis. It's a technology that uses a semi - permeable membrane to remove ions, molecules, and larger particles from water. The membrane allows water molecules to pass through while blocking most of the contaminants. It's like a super - fine filter that can separate the good stuff (pure water) from the bad stuff in the water.

Now, why is this so crucial in electronics manufacturing? Well, electronics are extremely sensitive to impurities. Even the tiniest bit of contaminants in the water used during the manufacturing process can cause big problems.

One of the main applications is in the cleaning process. When making electronic components, they need to be cleaned thoroughly to ensure proper functionality. Impure water can leave behind residues on the components. These residues might contain minerals, salts, or other particles that can corrode the delicate circuits over time. Using water purified by an RO membrane helps prevent this corrosion. For example, in the production of printed circuit boards (PCBs), any leftover impurities from the cleaning water can lead to short - circuits or reduced performance of the board. With RO - purified water, the components come out clean and free from these potential hazards.

Another important area is in the cooling systems of electronics manufacturing facilities. Many high - tech manufacturing processes generate a lot of heat. Cooling systems are used to keep the equipment at an optimal temperature. If the water in these cooling systems has impurities, it can form scale on the cooling pipes and heat exchangers. This scale acts as an insulator, reducing the efficiency of the cooling system. Over time, it can also cause blockages in the pipes, leading to costly repairs and downtime. RO membranes ensure that the water used in these cooling systems is pure, preventing scale formation and keeping the cooling systems running smoothly.

In the semiconductor manufacturing process, the purity of water is of utmost importance. Semiconductors are the building blocks of modern electronics, and their production requires an extremely clean environment. Even a single particle of dust or a trace amount of a chemical impurity can ruin an entire semiconductor wafer. RO - purified water is used in multiple steps of semiconductor manufacturing, such as wafer cleaning, etching, and rinsing. It helps maintain the high - quality standards needed for these precision components.

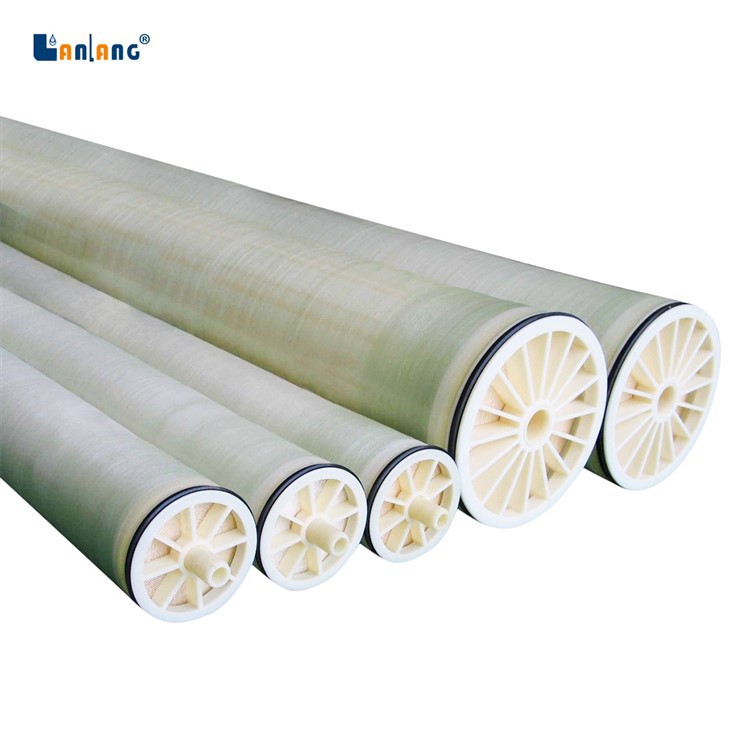

When it comes to the types of RO membranes we offer, we have a great selection. For instance, our RO Membrane for Water Treatment Machinery is specifically designed for water treatment equipment used in electronics manufacturing. These membranes are highly efficient at removing a wide range of contaminants, ensuring that the water meets the strict purity requirements of the industry.

Our 8040 RO Membrane is another popular choice. It's known for its high flow rate and excellent rejection rate of impurities. This means it can purify a large volume of water quickly while still keeping the water extremely pure. It's suitable for large - scale electronics manufacturing facilities that need a continuous supply of purified water.

We also have a comprehensive RO Membrane Series. This series includes membranes with different pore sizes and rejection rates, allowing us to meet the specific needs of different electronics manufacturing processes. Whether it's a small - scale operation or a large - scale industrial facility, we can provide the right RO membrane solution.

In addition to these technical benefits, using RO membranes can also lead to cost savings in the long run. While the initial investment in an RO membrane system might seem a bit high, the reduced maintenance costs and the improved quality of the electronic products make it a worthwhile investment. Fewer damaged components mean less waste and lower production costs. Also, the longer lifespan of the manufacturing equipment due to the use of pure water in cooling and cleaning systems reduces the need for frequent replacements.

If you're in the electronics manufacturing business and are looking for a reliable RO membrane supplier, we're here for you. We understand the unique requirements of your industry and can provide customized solutions. Whether you need a small - scale RO membrane system for a startup or a large - scale installation for an established manufacturing plant, we've got the expertise and the products to meet your needs.

So, if you're interested in learning more about our RO membranes and how they can benefit your electronics manufacturing process, don't hesitate to reach out. We're always happy to have a chat about your specific requirements and help you find the best solution for your business.

References:

- "Principles of Reverse Osmosis" by some water treatment experts.

- "Electronics Manufacturing Processes and the Importance of Water Purity" from industry - specific research papers.