As a supplier of Catalyst Resin, I often encounter inquiries regarding various technical aspects of our products. One question that frequently comes up is about the dielectric strength of Catalyst Resin. In this blog, I will delve into what dielectric strength means in the context of Catalyst Resin, its significance, and how it relates to our specific product offerings.

Understanding Dielectric Strength

Dielectric strength is a critical property of insulating materials, including Catalyst Resin. It refers to the maximum electric field that a material can withstand without experiencing electrical breakdown. Electrical breakdown occurs when the material loses its insulating properties and starts to conduct electricity, often resulting in a sudden and significant flow of current. This can lead to damage to the material and the electrical system in which it is used.

In the case of Catalyst Resin, dielectric strength is typically measured in volts per unit thickness (e.g., volts per millimeter or kilovolts per centimeter). A higher dielectric strength indicates that the resin can withstand a greater electric field before breaking down, making it a better insulator.

Importance of Dielectric Strength in Catalyst Resin

The dielectric strength of Catalyst Resin is crucial for several reasons. Firstly, in many applications, Catalyst Resin is used in electrical or electronic systems where it needs to provide insulation between different components. A high dielectric strength ensures that the resin can effectively prevent electrical leakage and short - circuits, thereby maintaining the proper functioning and safety of the system.

Secondly, in chemical processes where Catalyst Resin is used as a catalyst, electrical insulation can be important to control the reaction environment. For example, in some electrochemical processes, a well - insulated catalyst resin can help to maintain the desired electrical potential and prevent unwanted side reactions.

Factors Affecting the Dielectric Strength of Catalyst Resin

Several factors can influence the dielectric strength of Catalyst Resin:

- Chemical Composition: The chemical structure of the resin plays a significant role. Resins with more stable chemical bonds and fewer polar groups tend to have higher dielectric strengths. For instance, resins with a highly cross - linked structure are often more resistant to electrical breakdown.

- Purity: Impurities in the resin can act as conducting paths, reducing the dielectric strength. Therefore, high - purity Catalyst Resin is essential for applications where high dielectric strength is required.

- Moisture Content: Water is a good conductor of electricity. Even small amounts of moisture absorbed by the resin can significantly lower its dielectric strength. Proper storage and handling to prevent moisture uptake are crucial.

- Temperature: Generally, as the temperature increases, the dielectric strength of the resin decreases. This is because higher temperatures can cause the molecules in the resin to move more freely, making it easier for electrical breakdown to occur.

Our Catalyst Resin Offerings and Dielectric Strength

At our company, we offer a range of Catalyst Resin products, each designed to meet specific application requirements.

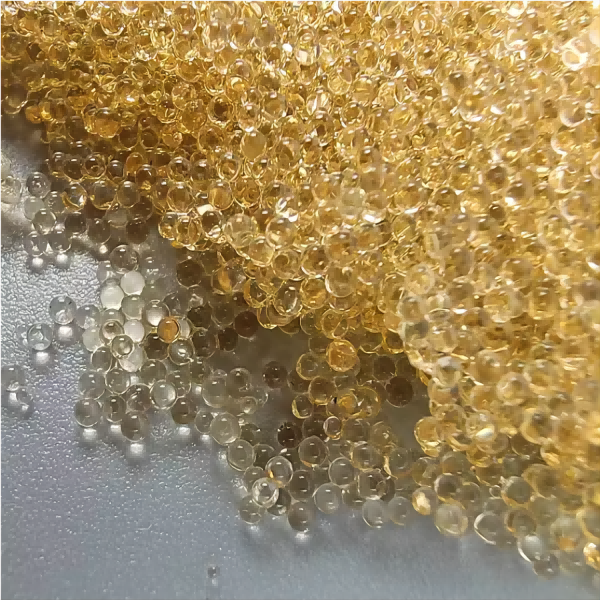

One of our popular products is the TY CS710 Gel Type Strong Acid Cation Exchange Resin. This resin is known for its excellent ion - exchange properties and also has a relatively high dielectric strength. It is carefully manufactured to ensure high purity and a stable chemical structure, which contribute to its good insulating performance.

We also have Catalyst Resin for Biodiesel Purification. In biodiesel production, electrical insulation can be important in some purification steps, especially in processes that involve electrical control. Our resin for biodiesel purification is formulated to have a suitable dielectric strength to ensure the reliability of the purification process.

Another product is the Catalyst Resin for Biodiesel Esterification. During the esterification process, the resin needs to maintain its insulating properties to prevent electrical interference and ensure the efficiency of the reaction. Our esterification - specific resin is engineered to have an appropriate dielectric strength for this application.

Measuring the Dielectric Strength of Catalyst Resin

To accurately determine the dielectric strength of our Catalyst Resin, we use standardized testing methods. Typically, a sample of the resin is placed between two electrodes, and a gradually increasing electric field is applied until electrical breakdown occurs. The voltage at which breakdown happens is then divided by the thickness of the sample to obtain the dielectric strength.

We conduct these tests under controlled conditions, taking into account factors such as temperature, humidity, and sample preparation. By regularly testing our products, we can ensure that they meet the specified dielectric strength requirements and provide consistent performance to our customers.

Applications and Dielectric Strength Requirements

Different applications have different dielectric strength requirements for Catalyst Resin.

In low - voltage electrical systems, such as some consumer electronics, a relatively lower dielectric strength may be acceptable. However, in high - voltage applications, such as power transmission and distribution equipment, a very high dielectric strength is essential.

In chemical processes, the dielectric strength requirements depend on the nature of the reaction and the electrical environment. For example, in some electrochemical cells, the resin needs to have a high dielectric strength to prevent short - circuits and maintain the stability of the electrical potential.

Quality Control and Dielectric Strength

We have a strict quality control system in place to ensure that our Catalyst Resin products meet the required dielectric strength standards. This includes raw material inspection, in - process monitoring, and final product testing.

During raw material inspection, we check the purity and chemical composition of the materials used to make the resin. In - process monitoring involves checking the manufacturing parameters to ensure that the resin is being produced under optimal conditions. Finally, every batch of finished product is tested for dielectric strength and other important properties before it is released to the market.

Future Developments in Catalyst Resin Dielectric Strength

As technology advances, there is a growing demand for Catalyst Resin with even higher dielectric strengths. Researchers are exploring new chemical formulations and manufacturing processes to improve the insulating properties of the resin.

For example, the use of nanomaterials in the resin matrix may enhance its dielectric strength by providing additional barriers to electrical conduction. Also, new cross - linking techniques can be developed to create more stable and robust resin structures.

Conclusion

The dielectric strength of Catalyst Resin is a vital property that affects its performance in various electrical and chemical applications. As a supplier, we are committed to providing high - quality Catalyst Resin products with reliable dielectric strength. Our TY CS710 Gel Type Strong Acid Cation Exchange Resin, Catalyst Resin for Biodiesel Purification, and Catalyst Resin for Biodiesel Esterification are carefully engineered to meet the specific needs of different industries.

If you are interested in our Catalyst Resin products or have any questions about dielectric strength or other technical aspects, please feel free to contact us for further discussion and potential procurement. We look forward to partnering with you to meet your Catalyst Resin requirements.

References

- ASTM D149 - Standard Test Method for Dielectric Breakdown Voltage and Dielectric Strength of Solid Electrical Insulating Materials at Commercial Power Frequencies.

- Handbook of Ion Exchange Resins: Their Application to Industrial Processes, by F. Helfferich.

- Journal of Applied Polymer Science, various issues related to the electrical properties of polymer - based resins.