Product Specification

The significant difference between producing granulate sugar and liquid sugar is crystallization. In the crystallization process, not only is water got separated from sugar but most of the impurities or non-sugar content are removed from the sugar crystal, turning into molasses. Therefore, in liquid sugar production, the demineralization process is introduced to ensure the quality of the product is as pure as refined sugar.

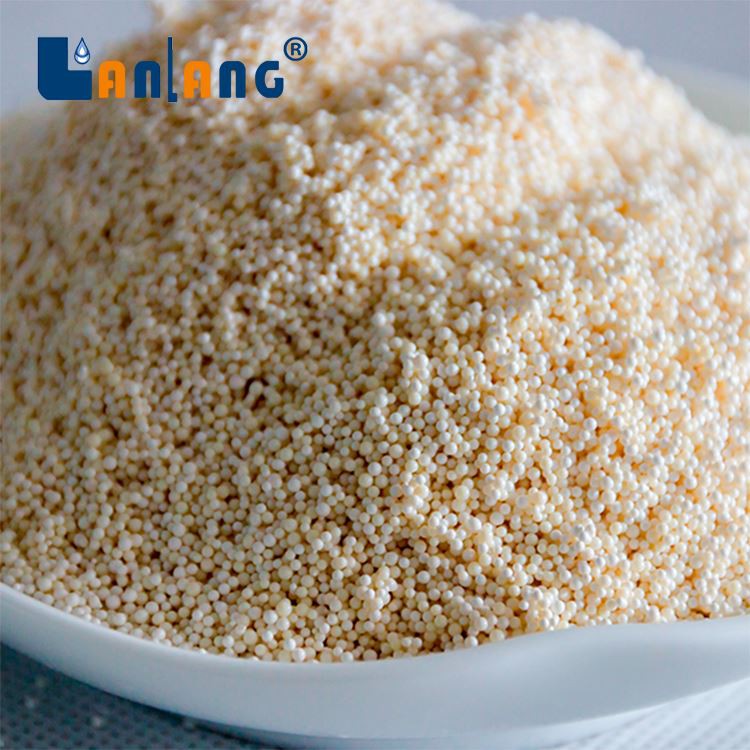

The most common technology for demineralizing liquid sugar is the ion exchange resin combination of strong base anionic and weak acid cationic forms. Any soluble ionic molecules shall be exchanged entirely with the resin, thus resulting in a highly purified syrup product. However, besides great benefits for demineralization, this process could also be costly and produces a large footprint from frequent regeneration if the input syrup is poor.

One of the main factors affecting the demineralization unit's cycle length is color load towards the process. Because the resin combinations are the strong base anionic type, which has great affinity towards colorants molecule, when syrup is not pretreated well, those colorants would be first to be adsorbed by resin so that the ionic impurities could not get removed. Therefore, ions could break through the column concisely, and the demineralization unit has to get regenerated.

Initial treatment of sugarcane yields raw sugar syrup that is yellow- or tan-colored, and that color must be removed before crystallization of white sugar. Filtration and precipitation can extract much of the color from the raw syrup, but the remaining color is mostlysoluble organic impurities that are difficult to remove. Lanlang Ion Exchange Resins are widely used for final decolorization.Their high capacity and physical stability offer industry-leading process reliability and low cost of total operations.

Cane sugar decolorization aims at removing the organic impurities which impart color to the sugar liquor. Sugar color is an important parameter in sugar manufacturing, and this process step ensures that color is not passed on to the food, beverage, and other products it later sweetens. Ion exchange resins as sugar decolorizers have considerable economic benefits, in addition, they are easy to automate, and they are smaller in size. The resins in the columns require periodical backwashing with sweet water for their regeneration.

|

Model |

Description |

|

TC007-H |

Amber gel type strong acid cation exchange resin in hydrogen form for sugar deashing. |

|

TA201D |

Macroporous type I strong base anion resin for decolorization. |

|

TA213D |

Macroporous type I strong base anion exchange resin, organic scavenger, sugar decolorization. |

|

TA301D |

Macroporous weak base anion exchange resin for decolorization. |

Certification

Hot Tags: ion exchange resin for decolorization of sugar liquids, China ion exchange resin for decolorization of sugar liquids manufacturers, suppliers, factory, Sugar Industry Ion Exchange Resin, Ion Exchange Resin for Sugar Industry, physical stability Ion Exchange Resin, Sugar Industry Anion Resin, Styrenic resins for Sugar Industry, sugar cane processing Resin