Product Specification

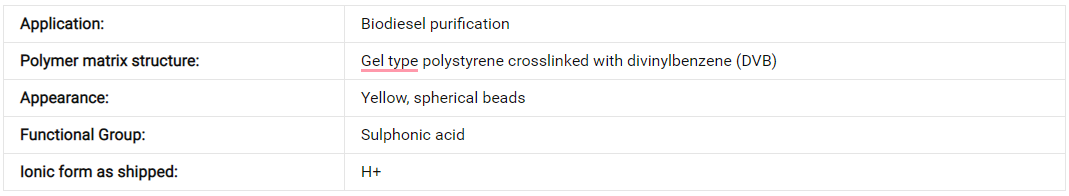

The Lanlang® TY BD452 is a cation exchange resin that contains a sulfonic group (-SO3H) within a styrene-DVB copolymer that features a clear and well-structured gel design. Lanlang® TY BD452 is an advanced solution for purifying biodiesel. As a biodegradable, renewable, and eco-friendly energy, biodiesel has gained unprecedented attention and popularity in the world in recent years. The increasing demand for biodiesel fuel and the pressing need for environmental protection, such as tackling climate change, have both contributed to its development. Therefore, the technology of biodiesel separation and purification plays a vital role in ensuring the quality of biodiesel production. By using Lanlang® TY BD452, we can produce high-quality biodiesel which is not only efficient but also environmentally friendly.

After biodiesel is made, it must be cleaned to remove impurities, including soap and glycerin. The traditional water wash method causes several problems, including possible emulsions and degraded biodiesel if the fuel is not dried adequately. It also creates a lot of waste water. Waterless methods of purifying biodiesel have been introduced into the marketplace, such as ion exchange resins and synthetic magnesium silicate.A number of different companies manufacture ion exchange resins (which are small polymer beads) to clean biodiesel. Although the products are similar, the companies'explanations of how the products work are sometimes very different.

For example, many companies say the beads work by exchanging ions (the sodium or potassium ions from the soap in the biodiesel are exchanged with hydrogen ions on the bead surfaces).The beads are presumed to work via ion exchange:they exchange a hydrogen ion with the sodium or potassium ion in the soap. Because the sodium or potassium portion of the soap is being held by the resin, the fatty acid portion is released into the effluent biodiesel, which will therefore have a higher percentage of free fatty acids. If the soap level in the biodiesel is higher than 2500 ppm, the biodiesel's acid value will likely exceed the ASTM limit of 0.5 mg KOH/g (the amount of KOH required to neutralize one gram of fuel).

Basic Features

Certification

Hot Tags: ion exchange resin for biodiesel purification, China ion exchange resin for biodiesel purification manufacturers, suppliers, factory, dry wash tower Ion Exchange Resin, industrial refining resins, alkylation Ion Exchange Resin, Ion Exchange Resin for Biodiesel Purification, industrial refining resins, Ion Exchange Resin for etherification